Oil injection Comp.

APM Series / INVERTER COMPRESSOR

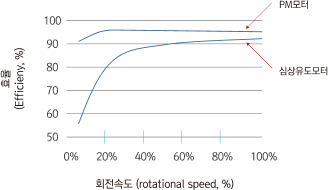

1. Advantages of Permanent Magnet Synchronous Motors (PMSM)

High efficiency, high power factor

Eliminates rotor excitation losses, increasing efficiency by 2-3%

Max motor efficiency of 96% for a 37kW permanent magnet motor

Rotor without electrical excitation, small inductance, high power factor

5-7% energy savings compared to asynchronous motors (induction motors)

Easy maintenance and cleaning of cooling cooler and fan

2. Wide Speed Control Range

Utilizes advanced control technology

Motor frequency range is 10~100%

No-load operation, no-load energy saving

(30HP 380V = 4A operation possible)

(50HP 380V = 5A operation possible)

3. Low Noise

Rational spatial application and magnetic field design

Wider range of application / Smaller operating noise

4. Compact Structure, Small Size and Light Weight

Small size, permanent magnet rotor with high power density

5. High Starting Torque

Starting torque of permanent magnet synchronous motor is up to 3 times greater than a three-phase induction motor

PM Motor Advantages

-

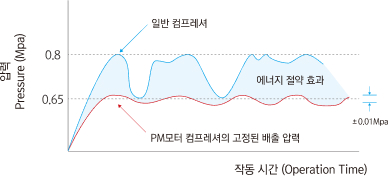

High Efficiency and Energy Saving

No current flows in the rotor

Capable of the same output as conventional motors with less power and no loss -

Stable Operation

Synchronous speed regardless of load

Enables stable operation due to synchronous rotation -

Reduced Maintenance Costs

Bearing grease replacement is difficult for small motors

PM motors have lower temperature rise, which increases grease life and, consequently, bearing life

-

Air compressor

Air single-stage compression design: 0.3MPa~1.60MPa

Volumetric efficiency of intake valve during compression ≥ 95%

Rotor diameter and center distance: Large

Low power consumption: Energy level

Efficiency index 1

-

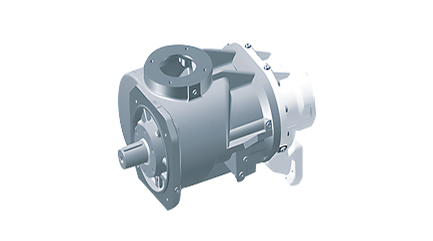

Air end

Direct drive: Gear ratio 1:1

Low noise

Rotor material: Special carbon steel SAE1141

Air end bearing: SKF

Operating temperature: MAX 115℃

-

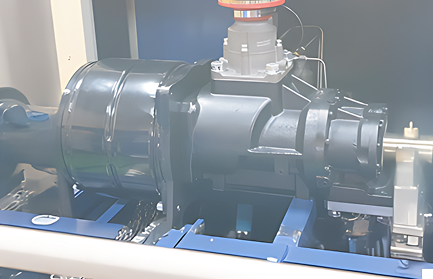

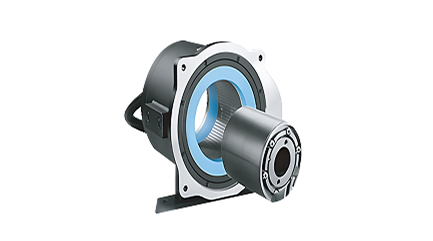

PM Motor (Permanent magnet motor)

High-efficiency permanent magnet motor: Motor efficiency ≥ 95%

Motor cooling method: Oil cooling

Protection level: IP65

Insulation class: F

B-grade temperature rise evaluation