Oil injection Comp.

APD Series / OIL INJECTION COMPRESSOR

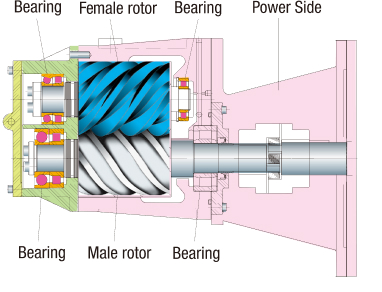

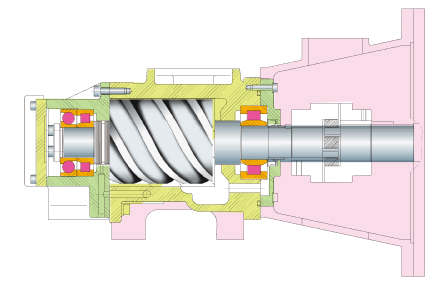

Direct Drive Air End

Direct Drive Air End

Structure and Features

-

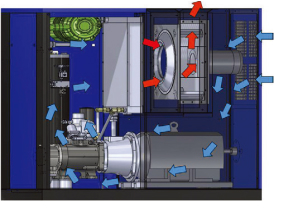

01 Maximize Cooling Efficiency

High-efficiency TURBO FAN and High-efficiency Cooler

Easy maintenance and cleaning of the cooler and fan

Application of advanced cooling technology

Sealed external cover structure using TURBO FAN

-

02 Simplification and Durability Reinforcement

Component integration and unification

Application of galvanized steel pipes to all oil filter lines

Adoption of verified high-quality components such as FUJI, YASKAWA, PARKER, HRC (Taper-Bushing), etc.

-

03 Enhanced Maintenance and C/S Convenience

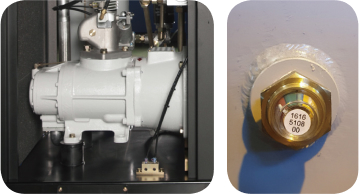

Equipped with a grease injection device

Easy-to-check Oil Level Gauge

Equipped with a hinge for separator replacement

ROTOR processing for all models using European grinding machine

Micom Controller

-

APC-4000 Controller

The LM Controller is designed based on accumulated diverse technology and experience to provide maximum satisfaction with minimal operation.

-

Display Details

Operating Message: Service pressure / Discharge air temperature / Operating hours / Fault input / Main motor 3-phase current (Option)

Operating Mode: Remote / Local mode, Auto / Continuous mode, Schedule operation

Error Message: Main motor overload / Fan motor overload / Discharge air temperature rise / Main motor reverse phase, phase loss / Pressure sensor disconnection / Temperature sensor disconnection

Warning Message: Consumable replacement / Air filter check / Separator check (Option) / Oil filter check (Option)

Other: Selectable discharge pressure units [kg/㎠] [Bar] [Mpa] [Psi], and temperature units [℃] [℉]

-

Passed Thermal Aging Test

The LM Controller has perfectly passed the Thermal Aging Test, guaranteeing high precision and long lifespan required by facilities such as nuclear power plants.

GHG Series / OIL INJECTION COMPRESSOR

Euro CE Certified

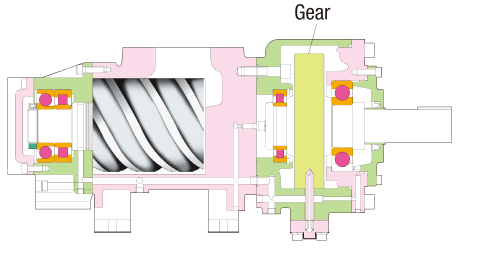

Medium Speed Gear AIR END

AGMA standard and JIS Class 1 helical gears are processed with high precision to achieve low noise.

직결구동 AIR END

Structure and Features

-

01 Structural Design and Function Addition Considering Maintainability

Each consumable component is placed on the side of the compressor for easy replacement.

-

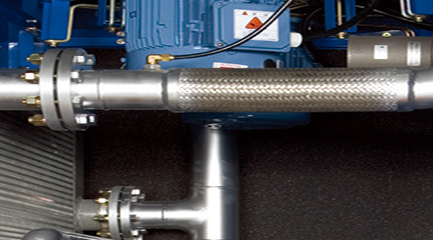

02 Steel Pipe Piping and Flange Connections for Easy Disassembly/Assembly

Convenient disassembly and assembly with the application of steel pipe piping and flange connections

Steel pipe piping and flange design enhanced for disassembly/assembly convenience

-

03 Newly Installed Simplified Oil Level Gauge

Equipped with an LM compressor, special material Oil Level Gauge supporting 20kg/㎠, always clean for semi-permanent use.

Applying New Technology

-

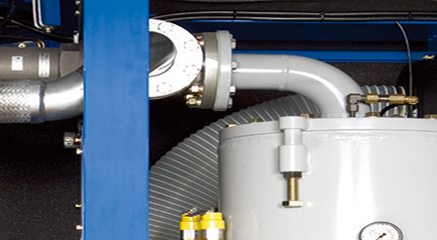

Maximize Oil Separation

The LM compressor supplements the conventional oil separation system by securing space within the Separator tank to buffer the flow velocity passing through the Separator Element.

This minimizes flow rate changes, reduces oil content in the discharged air, extends the lifespan of the Separator Element, and lowers maintenance requirements. -

New Unloading System

Applied an Unloading System that minimizes unnecessary power consumption during load operation.

Reduces power consumption by purging discharge pressure and achieves reliability and long life by adopting a new high-durability Unloading Valve made of new materials. -

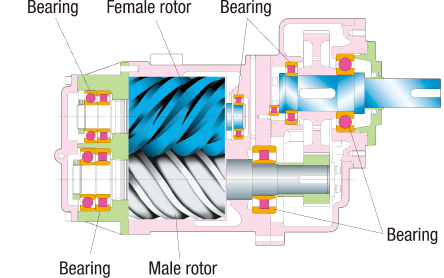

Efficient New Screw Rotor (UK HOLROYD Technology)

The LM compressor is equipped with a high-efficiency new Profile Screw Rotor utilizing the latest technology from HOLROYD, UK.

Optimized Seal Line length with Lobe count configured as 4:5

Minimized Blow Hole → Improved Volumetric Efficiency

Achieves low leakage and low required torque.

This allows it to produce uniquely high flow rates, showing the lowest leakage and highest power efficiency under optimal conditions.